Capabilities

Design Engineering & Manufacturing Capabilities

Naxnova’s advanced Screen Printing and other manufacturing capabilities turn

concepts into precision-engineered reality, setting new standards in quality and efficiency.

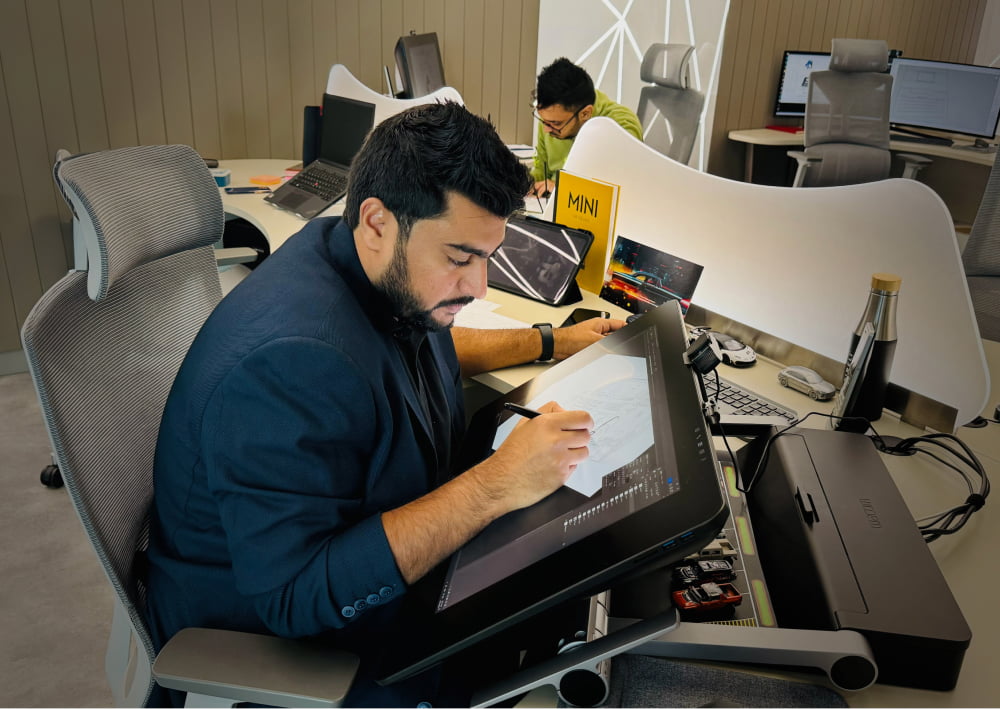

- Naxnova is a platform that integrates Design & Technology to bring out amazing & unique products.

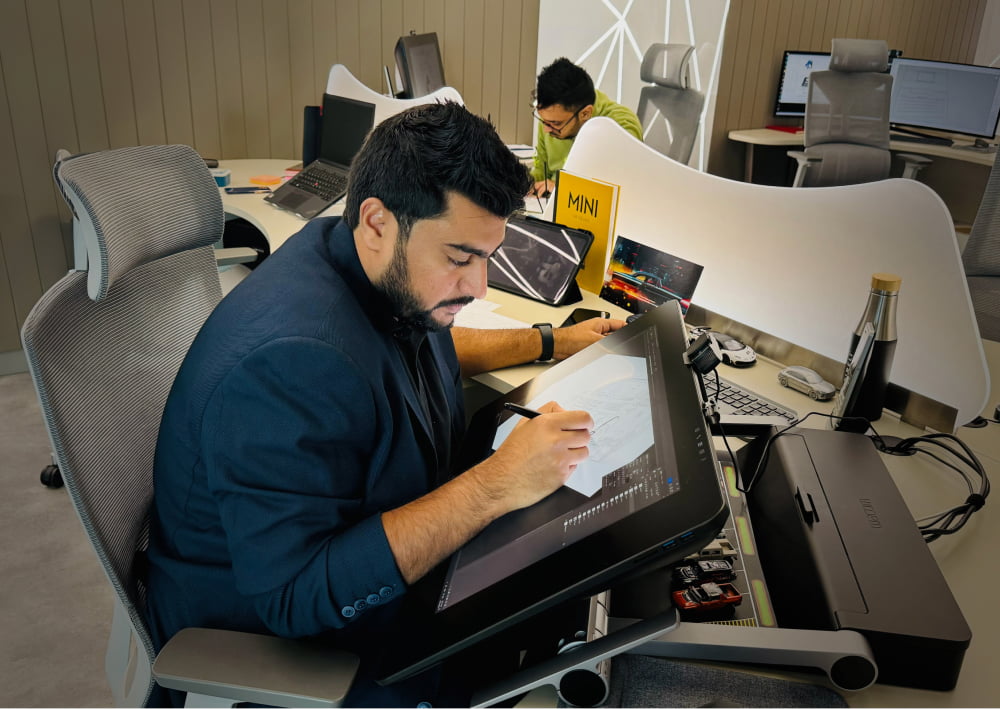

- We believe in the power of IMAGE. Our in-house Design & Engineering team is a blend of technical knowledge and creative talent. Understanding the science behind creating the product empowers us to offer amazing designs and products that give a leading edge.

- We extensively test products with speed to be ready to meet customers deadline.

- We offer comprehensive solution from Designing your Imagination, Engineering them to perfection & Manufacture in world class facilities to bring the best product to You.

- Two ‘Roll To Roll’ in-line screen printing lines.

- Automated high-speed cylinder printing machines coupled with wicket dryers.

- High-precision flatbed machines for large-format printing (12 feet x 8 feet).

- Vacuum forming machines to produce environmentally friendly, flexible 3D badges.

- Dedicated hybrid printed electronics facility with a Class 10,000 cleanroom (approximately 20,000 sq. ft. in size).

- State-of-the-art screen printing and curing setup with in-house functional ink manufacturing capabilities, including automated ink preparation facilities.

- Automated SMT (Surface Mount Technology) assembly and production line.

- High-pressure forming machine.

- Conveyorised and automated doming setup comprising 2 doming machines with robotic arms and a multiple nozzle dispensing system.

DESIGN ENGINEERING

- Naxnova is a platform that integrates Design & Technology to bring out amazing & unique products.

- We believe in the power of IMAGE. Our in-house Design & Engineering team is a blend of technical knowledge and creative talent. Understanding the science behind creating the product empowers us to offer amazing designs and products that give a leading edge.

- We extensively test products with speed to be ready to meet customers deadline.

- We offer comprehensive solution from Designing your Imagination, Engineering them to perfection & Manufacture in world class facilities to bring the best product to You.

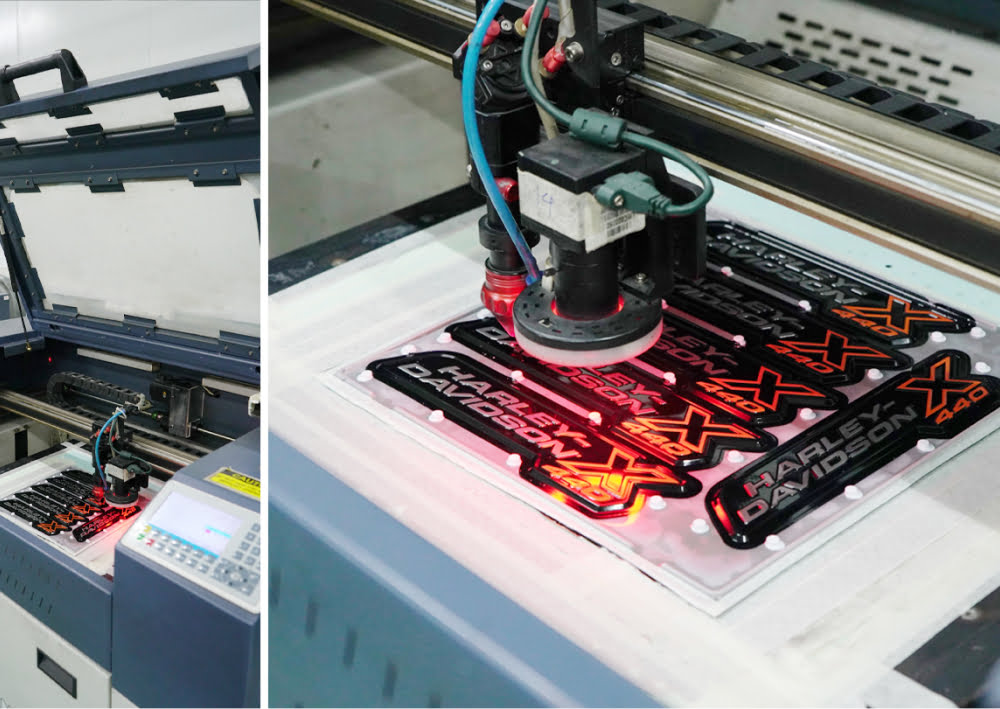

SCREEN PRINTING

- Two ‘Roll To Roll’ in-line screen printing lines.

- Automated high-speed cylinder printing machines coupled with wicket dryers.

- High-precision flatbed machines for large-format printing (12 feet x 8 feet).

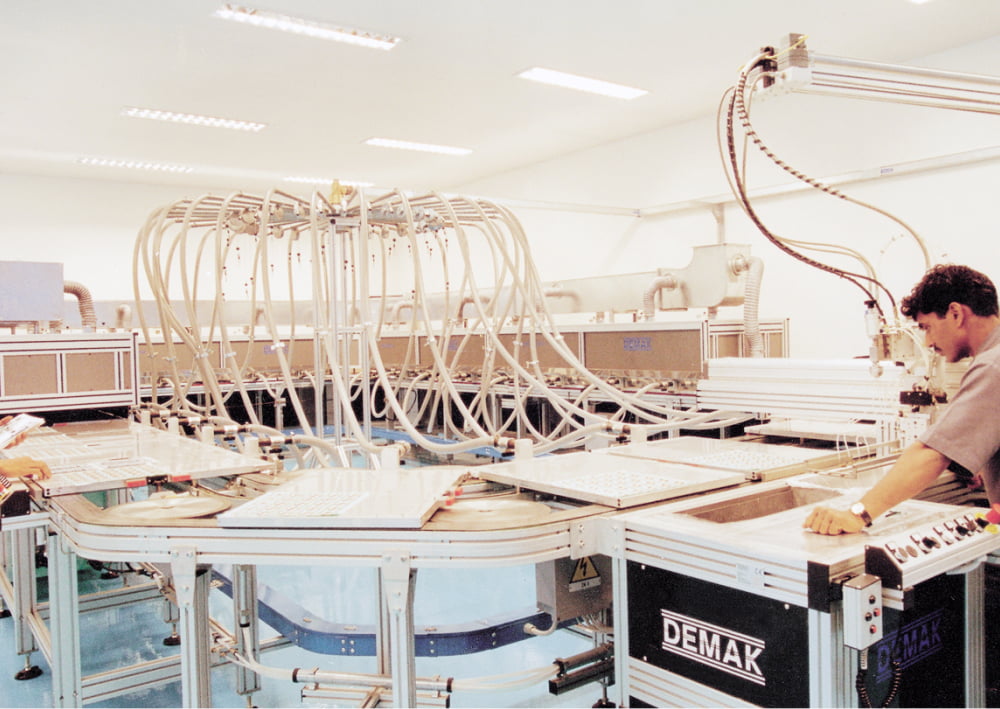

THERMOFORMING

- Vacuum forming machines to produce environmentally friendly, flexible 3D badges.

PRINTED ELECTRONICS

- Dedicated hybrid printed electronics facility with a Class 10,000 cleanroom (approximately 20,000 sq. ft. in size).

- State-of-the-art screen printing and curing setup with in-house functional ink manufacturing capabilities, including automated ink preparation facilities.

- Automated SMT (Surface Mount Technology) assembly and production line.

- High-pressure forming machine.

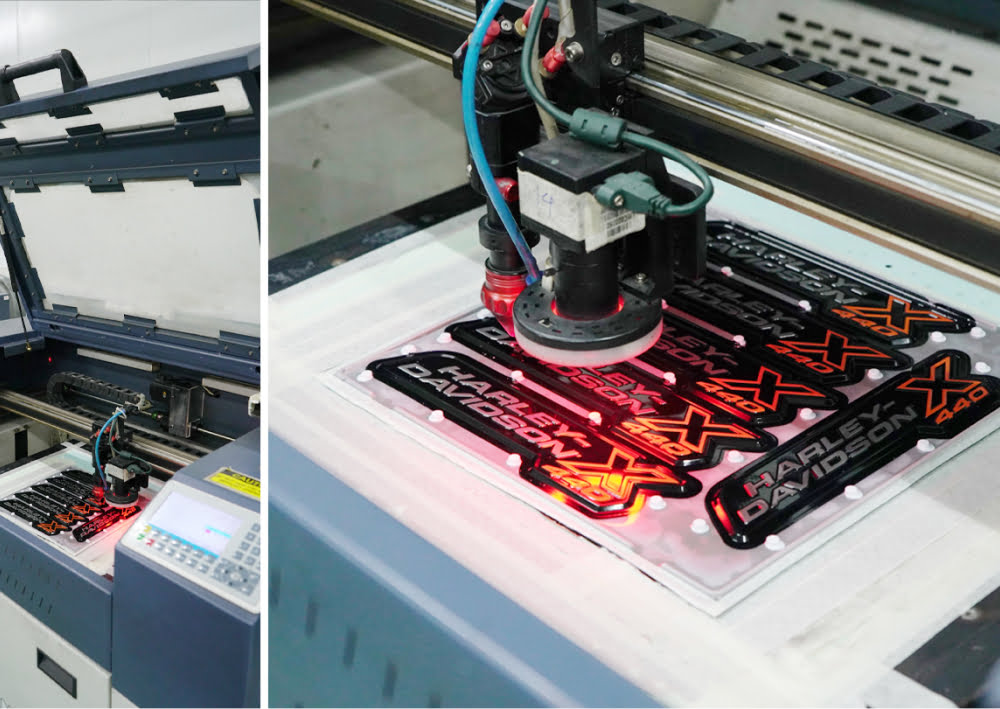

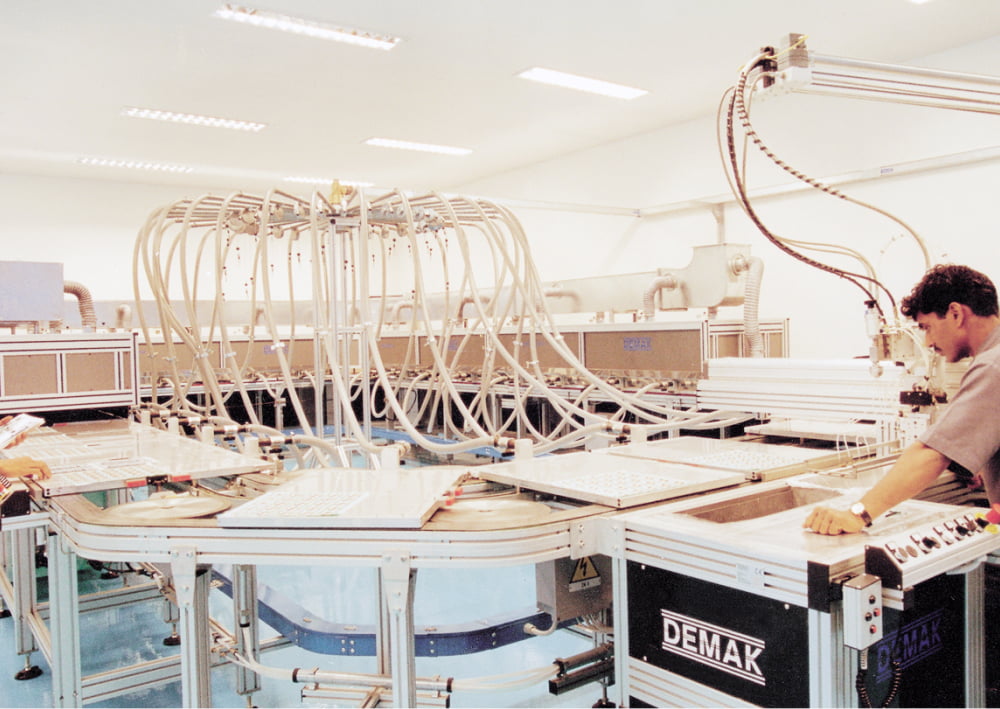

DOMING

- Conveyorised and automated doming setup comprising 2 doming machines with robotic arms and a multiple nozzle dispensing system.

QUALITY SYSTEMS

Quality Testing Capabilities

Advanced Comprehensive Quality Control Laboratory for Stringent

Physical, Mechanical, Chemical, and Weathering Testing Standards

Aesthetic Measurements

Gloss measure at 60°

by Glossmeter

Colour difference (ΔE)

by Spectrophotometer

Accelerated

Weathering Equipment’s

Xenon arc weather-o-meter

Xenon Arc Accelerated Weathering Chamber reproduces the damage caused by full-spectrum sunlight and rain. In a few days or weeks, the xenon weathering chamber can reproduce the damage that occurs over months or years outdoors.

QUV Test Chamber

The QUV accelerated weathering tester reproduces the damage caused by sunlight, rain and dew.

It simulates the effects of natural sunlight and artificial irradiance using special fluorescent UV lamps in the UVA, UVB, and UVC portions of the spectrum.

It simulates dew and rain with condensing humidity and/or water spray.

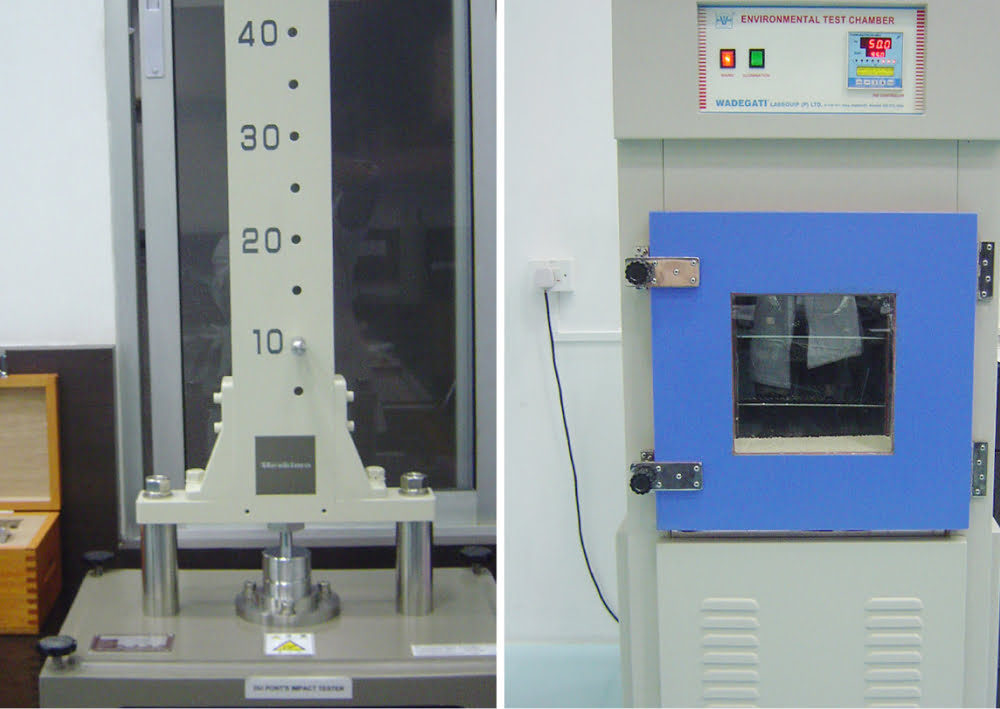

Durability

Measurements

Peel Strength Tester

To check the peel strength of the product at 180° peel as per ASTM D10000

Hot air Oven

Heat cycle involves heating the oven to the required temperature, maintaining that temperature for the proper time interval for that temperature

Salt spray test chamber

Salt spray test chamber is used to test the anti-corrosion quality of all the materials surfaces of painting, coating, electroplating in condition of salt spray environment.

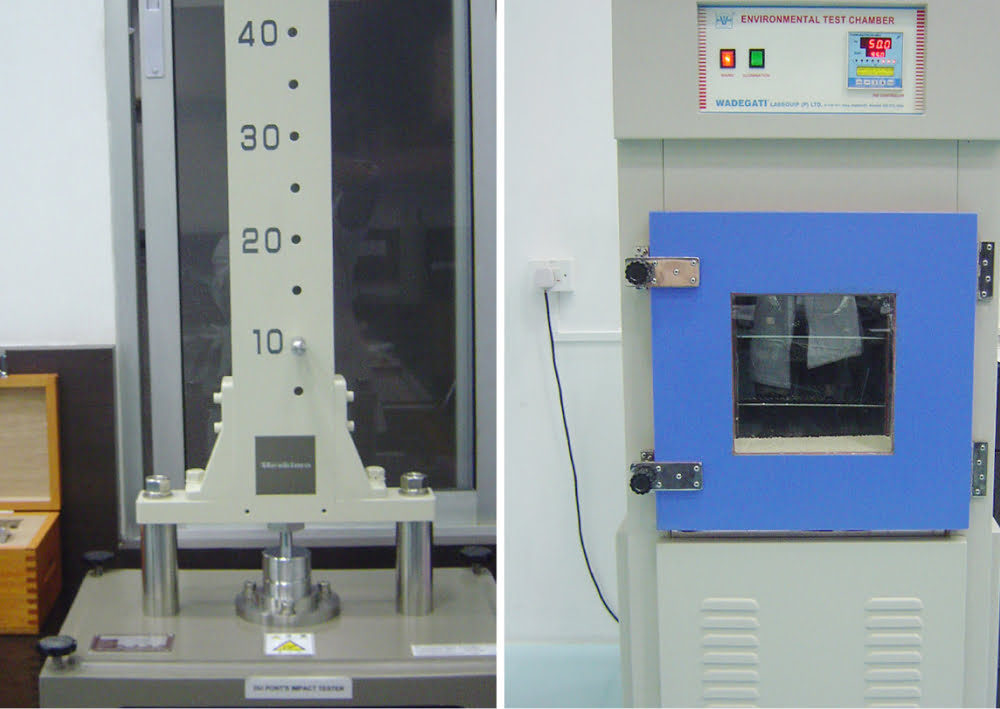

Environmental Test Chamber

Temp range -40℃ ~ +150 ℃

Humidity range 20% ~ 98% RH

Environmental test chambers are used to perform cold heat and humidity test, cold resistance test, thermal cycling test, ultra-low temperature test, high temperature test, storage condition

Quality testing steps

- Purity of Solvents

- Boiling water immersion

- Heat resistance & Shrinkage

- Constant load – travel speed test

- Gasoline/ fuel oil resistance

- Petrol resistance

- Acid resistance

- Alkali resistance

- Brake fluid resistance

- Engine oil resistance

- Detergent resistance

- Peel Strength at 180°

- Tensile Strength and Elongation

- Gloss test

- Cross-hatch adhesion test

- Spectrophotometer test

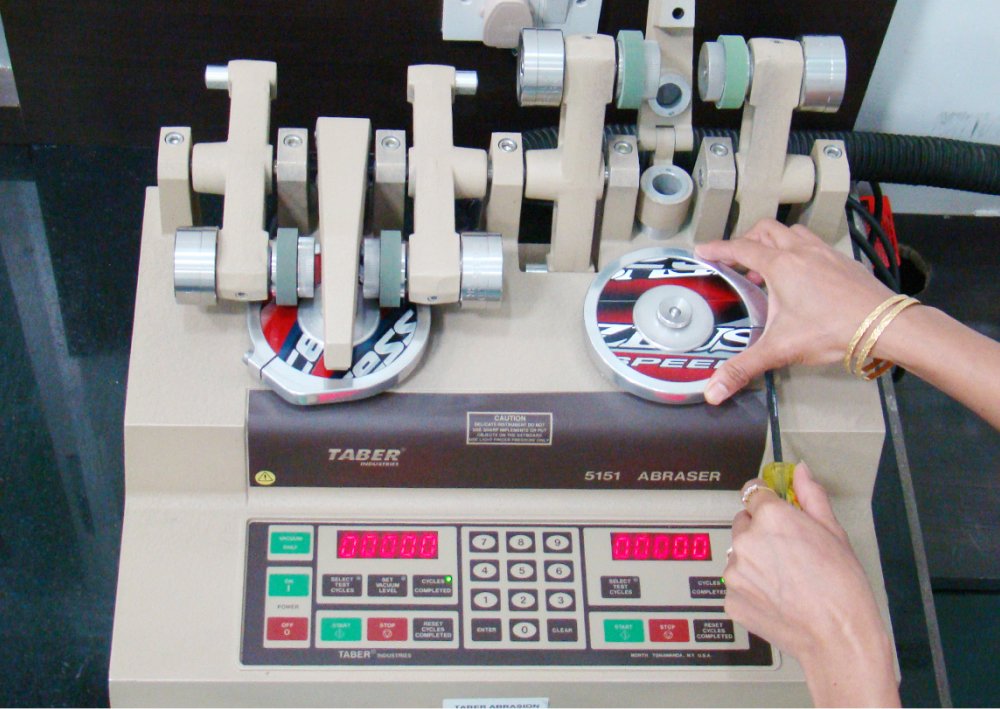

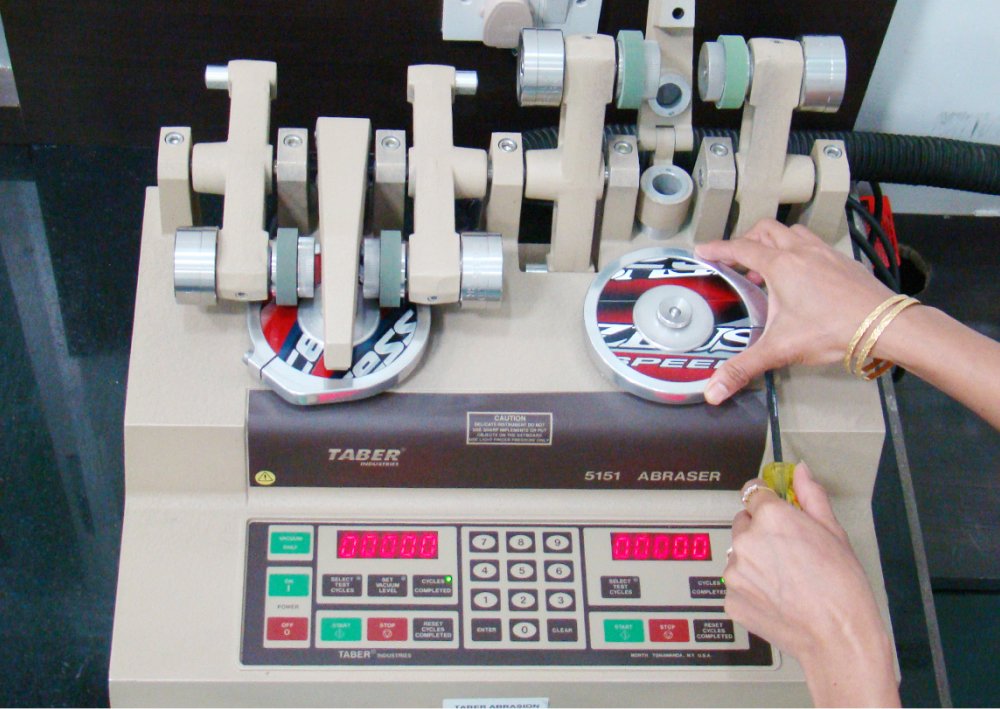

- Abrasion resistance

- Impact resistance at Normal temperatures and -15°C

- Thermal cycle resistance

- Humidity resistance

- Salt spray resistance

- Accelerated Weatherometer Testing as per SAE J1960/SAE 2527

Certifications

- IATF 16949: 2016 & ISO 9001:2015 Global Quality Management System

- ISO 14001:2015 Environmental management system

- ISO 45001:2018 Occupational health and safety management systems